Our technologies

Since 2016 Superfici has been offering 3D printing service, guaranteeing its customers competence, speed and professionalism.

Below are the main 3D printing technologies present in our laboratories

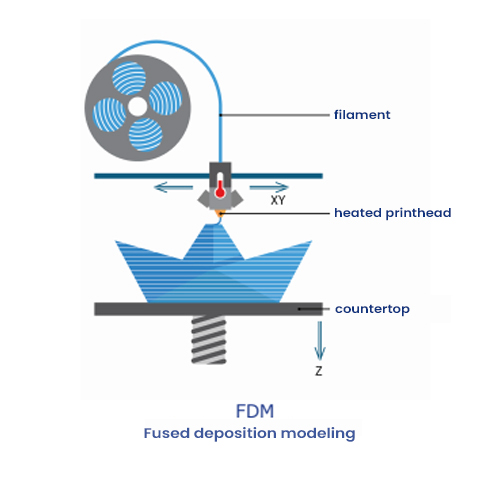

FDM

Principle and operation

Fused Deposition Modeling (FDM), otherwise known as Fused Filament Fabrication (FFF), is an additive manufacturing process belonging to the category of material extrusion, according to the ISO/ASTM 52900: 2015 standard.

In FDM, an object is constructed by selectively depositing molten material following a path determined by a software (slicer) dedicated.

The materials used are thermoplastic polymers and are loaded into the printer in the form of filament.

History

In 1988, S. Scott Crump, with the intention of creating a toy for his daughter, melted the plastic and distributed it in thin layers using a hot glue gun. He called this invention Fused Deposition Modeling (FDM) and filed its patent.

3D printing in FDM is the most advantageous economically technology to produce parts and prototypes with thermoplastic materials

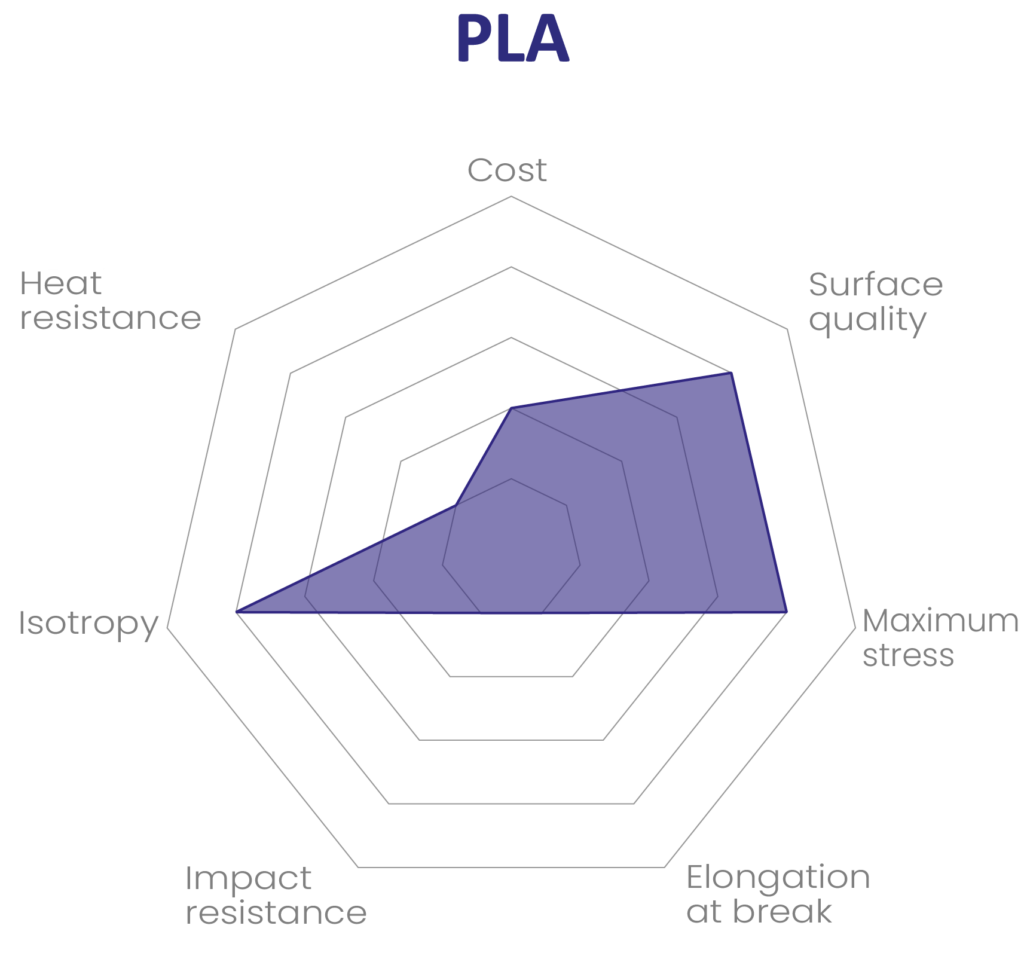

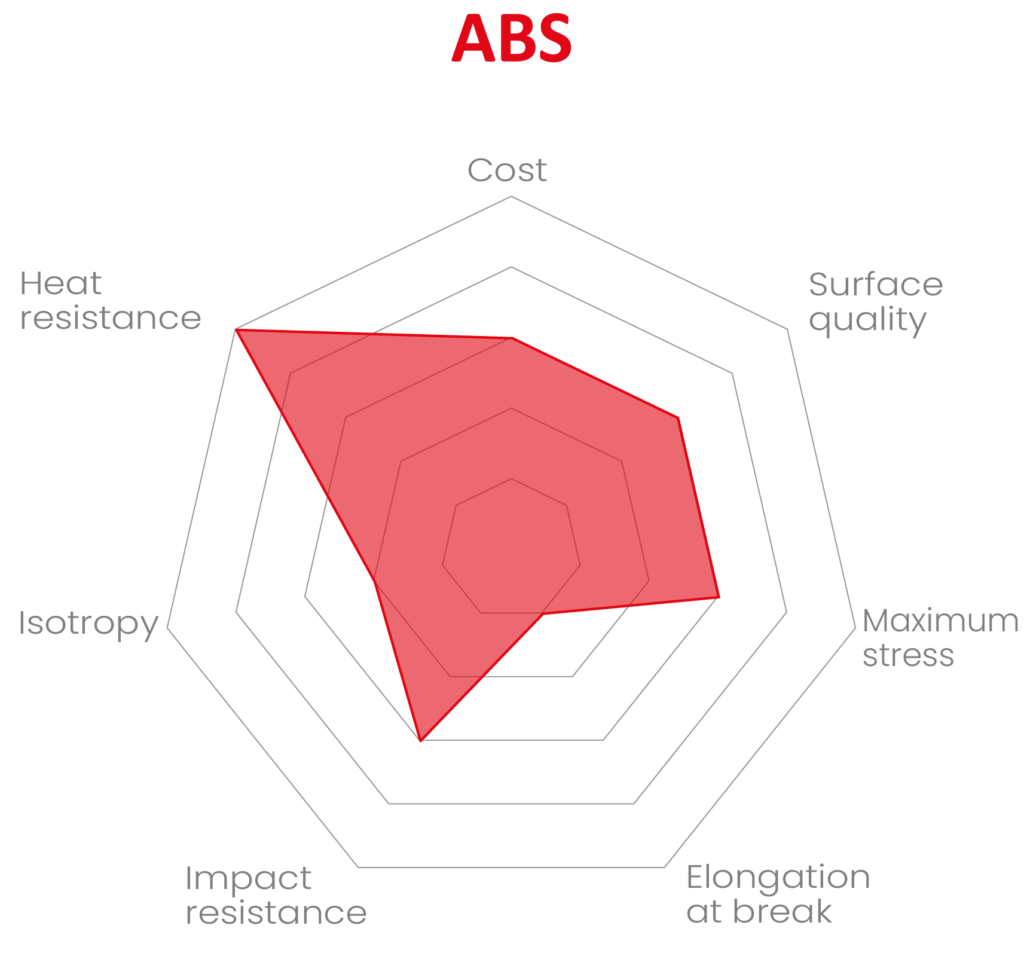

Materials

Do you want to know the complete range of materials that can be used in 3D printing and their main applications?

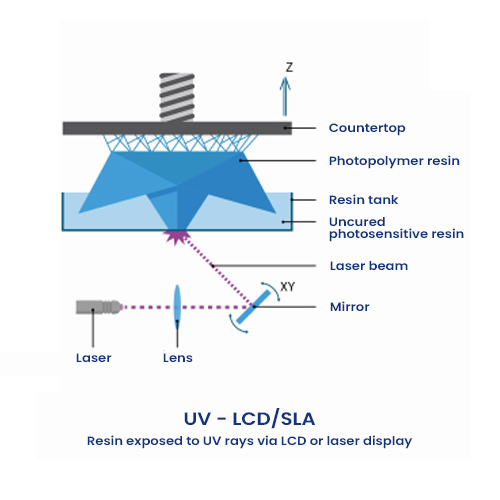

SLA/UV LCD

Principle and operation

Stereolithography (SLA) is an additive manufacturing process that belongs to the category of tank polymerization, according to the ISO/ASTM 52900: 2015 standard.

In SLA 3D printing an object is created by selectively solidifying, layer by layer, a photosensitive liquid resin by means of an ultraviolet laser beam.

The DLP and UV LCD technologies, very similar to SLA, use different UV sources to solidify the polymer layers.

History

The term stereolithography was coined in 1986 by Charles W. Hull, who conceived and patented the method of creating three-dimensional objects by the succession of solidified layers of resin sensitive to ultraviolet light.

About a year later, Larry Hornbeck invents Digital Light Processing technology, more commonly known as DLP.

SLA 3D printing can produce accurate parts, reaching the highest level of detail

Parts made from SLA have an excellent surface finish, ideal for aesthetic prototypes

Special materials are available for SLA, such as clear, flexible and cast-specific resins

Materials

The materials used in SLA 3D printing are photosensitive thermoplastic polymers, which appear in liquid form, and are activated by a laser source during the printing process.

Complete the form to receive the complete datasheet of materials that can be used with SLA technology and the main fields of application.

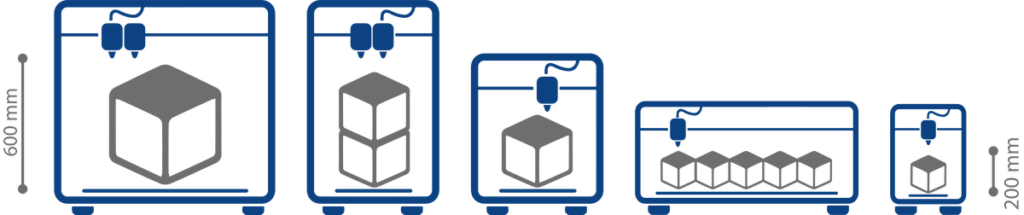

Our printers

SUPERFICI now has 14 3D printers with different formats and technologies

| AMOUNT | USABLE PRINT VOLUME | TECHNOLOGY | RESOLUTION |

|---|---|---|---|

|

AMOUNT

1

|

USABLE PRINT VOLUME

600 x 600 x 600 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

50 ÷ 1200 μm

|

|

AMOUNT

4

|

USABLE PRINT VOLUME

300 x 300 x 600 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

100 ÷ 800 μm

|

|

AMOUNT

2

|

USABLE PRINT VOLUME

250 x 700 x 200 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

100 ÷ 300 μm

|

|

AMOUNT

1

|

USABLE PRINT VOLUME

300 x 300 x 300 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

90 ÷ 290 μm

|

|

AMOUNT

2

|

USABLE PRINT VOLUME

200 x 200 x 180 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

90 ÷ 290 μm

|

|

AMOUNT

1

|

USABLE PRINT VOLUME

180 x 180 x 280 mm

|

TECHNOLOGY

FDM

|

RESOLUTION

50 ÷ 290 μm

|

|

AMOUNT

1

|

USABLE PRINT VOLUME

ø180 x 180 mm

|

TECHNOLOGY

SLA

|

RESOLUTION

25 ÷ 100 μm

|

|

AMOUNT

2

|

USABLE PRINT VOLUME

132 x 74 x 175 mm

|

TECHNOLOGY

UV LCD

|

RESOLUTION

25 ÷ 100 μm

|