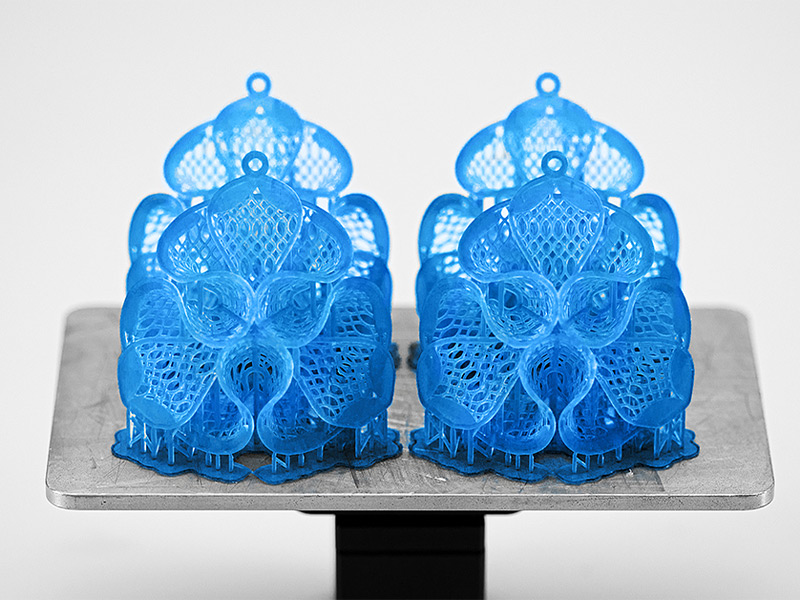

Discover 3D printing

Additive manufacturing

Additive manufacturing allows the creation of objects by adding material.

The source is a digital 3D model, generated with dedicated software, which can be subsequently processed in order to be created with different technologies.

The result of this process, commonly known as 3D printing, is free from the constraints typical of other production methods, not requiring the use of molds and minimizing production waste.

This translates into a reduction of times and costs of production, especially for prototypes, unique pieces (one-off), or short runs, guaranteeing a high possibility of customization and continuous implementation, at no additional cost.

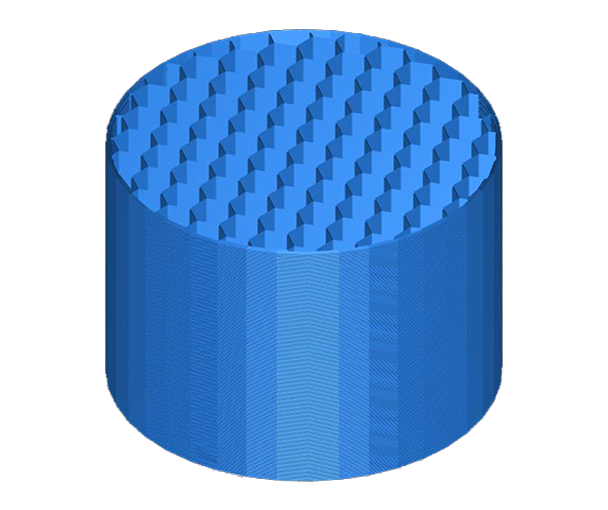

Resolution

The print resolution, commonly known as "layer height" can be defined in advance and can vary according to the technology and materials used.

Variable density

Not being machined from solid, each object made in 3D printing can be lightened internally, saving weight and reducing material waste.

Undercuts

3D printing does not require draft angles or decomposition in the case of undercuts, guaranteeing a product free from geometric constraints.

Fields of application

Prototyping

Model making

Molds

Engineering

Flexible prototyping

Dental

Jewelry

Didactics

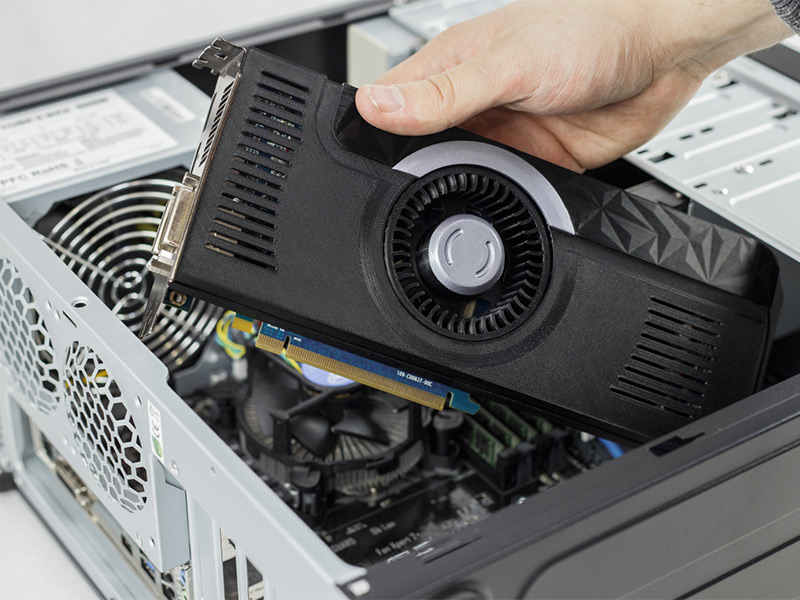

Electronics

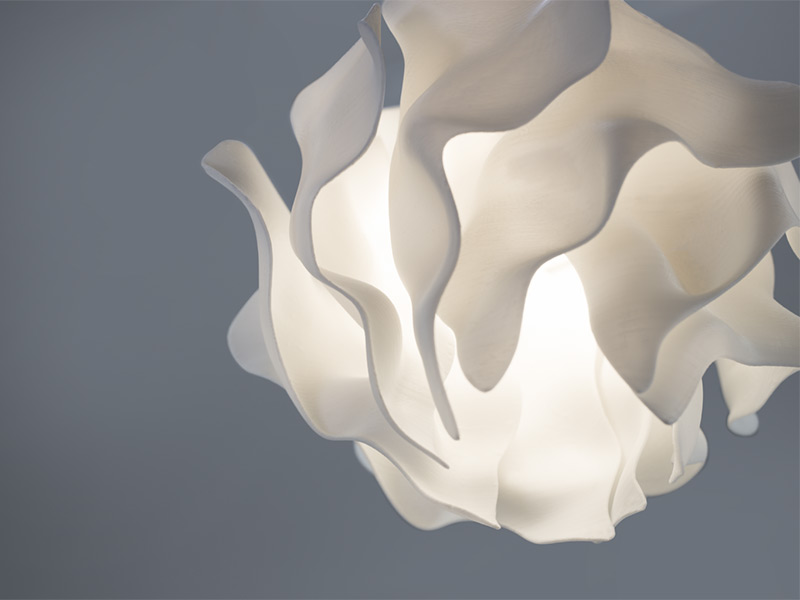

Lighting technology

Fashion

Automotive

Enter the world of 3D printing

In a market increasingly inclined to digitization and based on speed and customization, 3D printing is the ideal technology to innovate and make your company competitive.