On-board components

100% design freedom

Thanks to 3D printing you can create components with complex geometries, with complete design freedom.

Functionality and aesthetics come together in additive manufacturing, eliminating the need for production molds and minimizing processing waste.

Without molds, even geometries with undercuts can take shape.

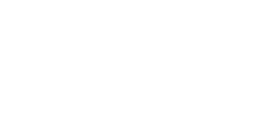

Technological integration

The high degree of geometry control allows the integration of components, technological elements and instrumentation already in the design phase, simplifying and speeding up the assembly and set-up phases.

The peculiarities of 3D printing also allow you to manage and design the object in its entirety, allowing you to obtain technical steps or position sensors inside the product.

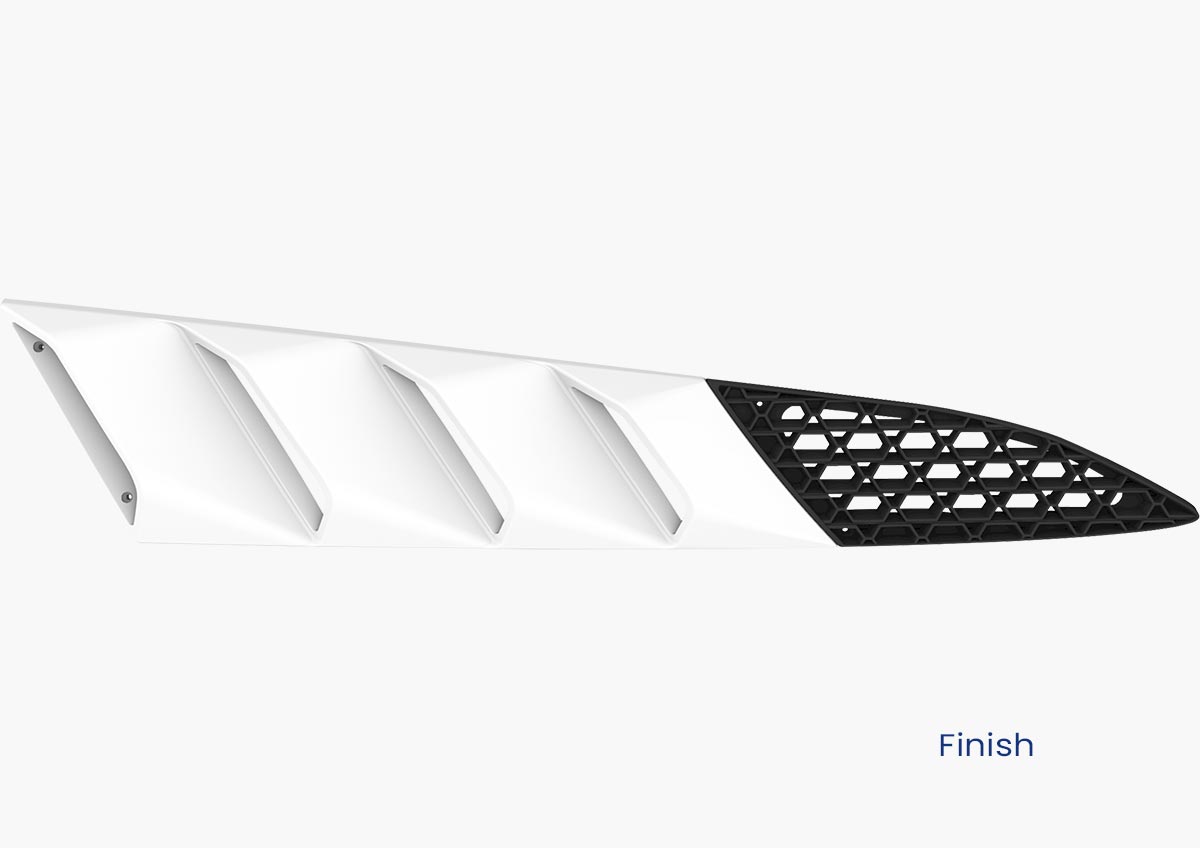

High level of finish

Do you want to make an on-board component with 3D printing?

Case studies

Fly Amer 94' dashboard

Goal

Engineering and construction of the fly bridge, designed for fixing on board with instrumentation.

technology

3D printing – FDM

material

Superfici-PLA HT

Size

110x75x62cm

Tankoa 70mt speaker support

Goal

Concept, design and construction of built-in support for audio speakers.

technology

3D printing – FDM

material

Superfici-ABS BV

Size

15x12cm

Hard-top component

Goal

Aesthetic fin for hard-top with possible integration of technology.

technology

3D printing – FDM

material

Superfici-PLA

Size

60x25x15cm

Cut-out

Goal

Have a template that fits perfectly on a complex surface to make holes

technology

3D printing – FDM

material

Superfici – PLA

Size

10x12x1.5cm